Put your Best Waste Forward

Your old t-shirt could find a better home than a landfill

The waste issue in our world today is a sizable one, and recognizing the severity of it can feel daunting. We have a trash pile the size of Texas in the middle of our ocean. We’re depleting our resources at an unsustainable rate. And what does “sustainable” mean anyway? To ensure a successful and plentiful future, we must focus on producing in a way that does not take more than it gives. Our industrial processes must ensure longevity through renewable practices, rather than ensuring output at a rate that cannot be upheld with the resources we have.

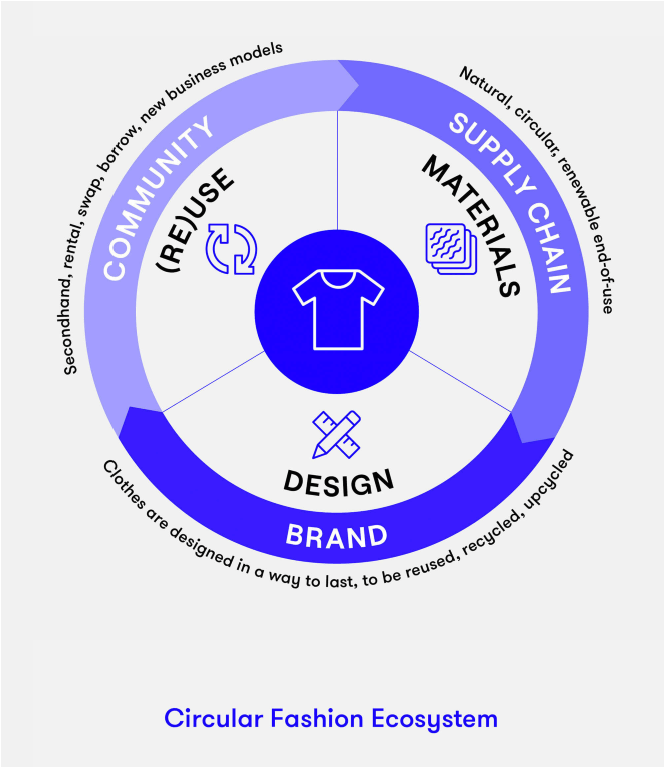

Historically, fashion and apparel industry has been a huge contributor to unsustainable business practices, resulting in increased waste, carbon emissions, overconsumption of natural resources, and more. By focusing on efforts such as circularity, businesses are shaping the way we look to become more sustainable as a whole.

“Transforming the fashion industry from its linear ‘take, make, waste’ model to a circular one, where materials are perpetually recycled, is considered the ‘holy grail’ of sustainability.” Forbes

In the simplest terms, circularity ensures that there is no end life for a given product. Instead of going from assembly to consumer to landfill, circular business practices ensure the re-use or repurposing of products to reduce waste and overconsumption of resources. According to Vogue Business, a “vast quantity of product ends in landfill but is easily resellable”. Not to mention the amount that isn’t resellable as is, but could be repurposed into material for another item. The goal of circularity is “to make fashion traceable, transparent and more sustainable for businesses, consumers — and the planet” (Vogue Business, “Fashion’s circular economy could be worth $5 trillion”, November 2020).

“The amount of time, energy, and resources that go into those trashed items is usually disproportionate to their quick turnaround; a single cotton T-shirt may require up to 700 gallons of water and may travel across several countries during production. But even if it’s stained or damaged at the end of its life, it could likely be recycled into something else, like housing insulation or even another T-shirt.“

The consumer landscape is beginning to feel more and more split. With the rise in ethics-focused buyers, companies boasting sustainable practices, slow fashion, and fair working conditions are becoming more commonplace. At the same time, we’re consuming at a rate higher than ever before. Fast fashion promises current trends at a much cheaper cost. But what happens to those trendy sandals when they’re out of style next season? Items like shoes often get thrown away because they get dirty, wear out easily, and people don’t like the idea of wearing another person’s used shoes. Companies like Thousand Fell are finding ways to combat this very issues—they “offer vegan sneakers on a closed-loop model: Wear them out, send them back, and they’ll be recycled into other sneakers—and you’ll get a credit for a new pair” (Vogue, “The Future of Fashion Is Circular”, 2019.). Sounds like a good alternative to throwing them away, if you ask me.

In fact, Stacy Flynn, the CEO of Evrnu (a company that “breaks cotton waste down into a liquid, then remakes it into stronger, higher-performing fibers”) urges us to “get used to looking at things and understanding that nothing actually goes ‘away’ [when we throw it out]—there is no ‘away,’” (Vogue, “The Future of Fashion Is Circular”, 2019.). All our waste goes somewhere. Oftentimes, our waste can take centuries to break down. So what’s the alternative? Circular models of business, as a means of ensuring that our businesses can continue to operate—and we all can continue to thrive.

Don’t Call it a Comeback, Baby

How today’s “sustainable practices” were once our normal, and why we must return to them

We know that our current production models and overconsumption leads to too much waste. It’s not a problem that’s slowing down any time either. In November of last year, Forbes reported that “with global apparel consumption projected to rise by 63% to 102 million tons in 2030, and an increase in clothing being sent to landfill accordingly…achieving circularity is becoming even more critical.” We’re quickly learning that our production to landfill pipeline is to blame. The mass industrialization of business sectors like agriculture is actually decreasing biodiversity and the amount of healthy land we have to use. According to Fast Company, “experts estimate that big agriculture is responsible for roughly 30% of global carbon emissions, 70% of freshwater use, and 60% of the loss of biodiversity”, resulting in an estimated 60 growing seasons left until our soil is unable to produce agriculture.

“Today, farmers around the world use modern techniques such as pesticides, irrigation systems, and monocropping (planting a single crop such as cotton) to increase their yields. They then sell their crops to middlemen, who bundle the materials together and sell them on the commodity market to mills.” Fast Company

The good news is that these ecosystems could bounce back relatively quickly if we take the right steps. Aras Baskausas, CEO of Los Angelesbased fashion company Christy Dawn, noted how after pushing efforts in their own sustainable practices, they’ve “discovered that regenerative farming is really nothing new. It’s just returning to ancient farming methods that have been passed down from generation to generation.”

Ultimately, regenerative farming, like circularity, ensures we can keep producing and consuming without causing damage to the very resources we depend on. These practices, according to Jeff Tkach, Chief Innovation Officer of the Rodale Institute, make “the crops healthier, which ultimately improves the profitability of the farm.”

At the end of the day, unfettered production is a way to make a quick buck, but only sustainable, regenerative practices and circular models will ensure your long-term success.The problem with many companies is that they’re out of touch with their sources, and may not even be aware of the damage they’re causing by working with certain farmers, materials, etc. Visibility and transparency at the very core of your business is going to be the only viable path forward.

MOVES IN THE CIRCULARITY SPACE

The New Cotton Project has 12 members, including H&M and Adidas. Forbes reported on the “highly novel” nature of this project, in that it “unites companies who compete in the market, but also recognise that collaboration is needed to achieve circularity at the industry level.” These industry giants will test the “new cotton”, which, according to The New Cotton Project, is “a new, man-made cellulosic fiber that looks and feels like cotton” and is made out of textile waste that has been “collected and sorted, and regenerated…using Infinited Fiber Company’s textile fiber regeneration technology”.

More Data, More Options

How Vi3 can track your product’s life cycle from beginning to new beginning

Circularity is a way to envision new life for your products while contributing to a more successful future for all. As Bethany Williams told Harpers Bazaar, “It’s about trying to make a cycle of production rather than just a production line. It’s a different way of operating.” It’s time to take a look at ever step of your production process—to work with suppliers using regenerative practices, and implement systems for collecting and repurposing your final product after it’s been sold.

“Over the past 40 years, the $1.3 trillion fashion industry has created a vast, complex supply chain. Most brands work with factories and mills to make clothes, but few go all the way back to the farms where the cotton, wool, or rubber is produced. That’s beginning to change.”

While circularity is still a relatively new concept, it’s important to start visualizing how this practice could be implemented in your business. As Vogue noted, the goal of circularity is to “to make fashion traceable, transparent and more sustainable for businesses, consumers — and the planet”. We at Vi3 know there’s no transparency without accurate data. Our V Source tool grants unprecedented insight into your supply chain, ensuring your materials are only coming from sources you approve. We are also able to give you a view into the post-production life cycle of your product. With V Connect, you’re able to pinpoint consumer engagement with the product through hyper-unique scannable materials. Our technology would allow you to pinpoint which product’s life cycle stops at the consumer, and which are returned to you for repurposing. The possibilities truly extend the entirety of the future’s circular model of production, consumption, and re-production. Wouldn’t you want to know how well you’re doing? Reach out to one of our experts today.