Supply Chain Snafu

Understanding what recalls are

Recalls are bound to happen, but there are steps businesses can take to help minimize both their frequency and impact. One of the most important things for businesses to understand is that for a brand to bounce back from a recall crisis, there must be a plan in place for managing such a crisis, before it actually happens. It’s imperative for businesses to take a proactive rather than a reactive approach. While we’ll dive into how companies can be more proactive later on in this white paper, it’s important to understand recalls— what they are, how they happen, and how they can affect you.

According to Investopedia, a “product recall is the process of retrieving and replacing defective goods for consumers. When a company issues a recall, the company or manufacturer absorbs the cost of replacing and fixing defective products, and reimbursing affected consumers when necessary.” If this sounds like a lot of work, that’s because it is.

Recalls require identifying which of your products are defective or contaminated, alerting affected consumers, receiving their returns, and implementing some kind of makegood with the consumer. Going through this process requires not only tons of resources to identify and trace the physical goods, but also a lot of effort on the PR side to help control the narrative around a brand’s reputation.

Unfortunately, recalls are becoming increasingly more common. Because of strides in transportation, supply chains have become a lot more decentralized. “A number of everyday products contain parts manufactured from around the world. In an attempt to remain competitive, companies have increased global supply chains, offshoring, and outsourcing at the cost of product reliability” (Investopedia).

The more stops a product has to make before it reaches the consumer, the less oversight there is and the greater the opportunity for something to go wrong.

Just earlier this month, multiple sunscreen companies such as Neutrogena, Sun Bum, and CVS Health, had to recall some of their products because “Valisure, a Connecticut-based online pharmacy and laboratory, found dozens of popular sunscreen products have been contaminated with benzene” (USA Today). Benzene is a toxin that, when you’re exposed to high levels over time, can cause cancer. According to an article by CNN, “no one knows for sure how the toxin ended up in sun care products. Benzene was not an ingredient in any of the sunscreens, so experts suspect contamination had to have occurred during the manufacturing process.”

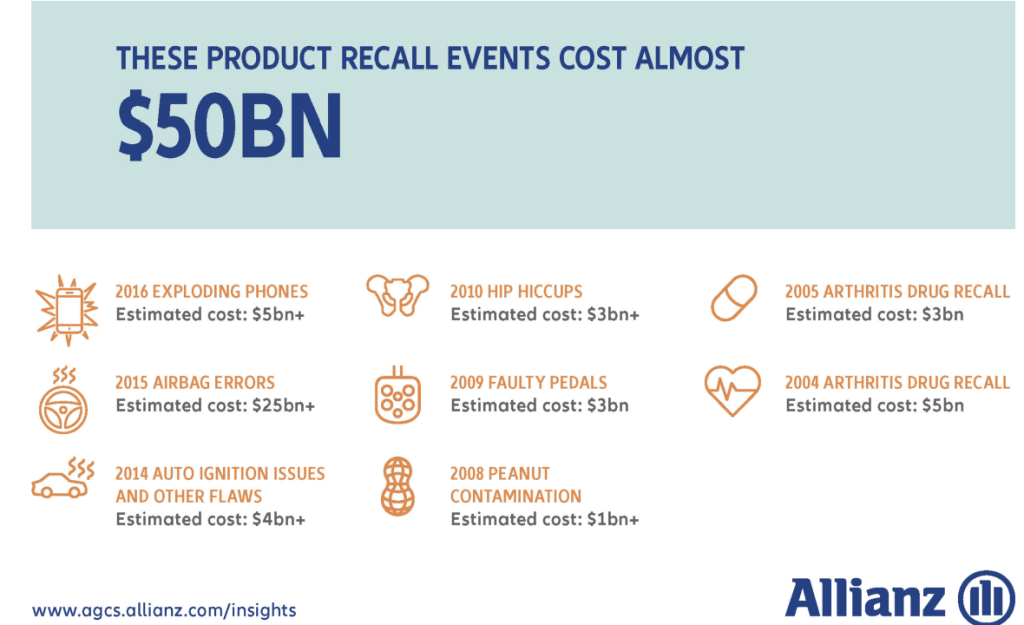

Given that we’re at the height of summer, when sunscreen sales are at their peak, it’s a pretty bad time to have to issue a recall. Companies that have highly-traceable supply chains are better prepared to handle recalls, because they’re able to more easily figure out where contaminations like this occurred, and isolate which inventory was affected, without recalling more product than is necessary. Especially when poorly handled, recalls can cost your company millions, even billions of dollars depending on the scale, as well as tarnish your brand’s reputation. It’s important to understand the many facets of recall management, so that you can be better prepared in the event of one.

The more stops a product has to make before it reaches the consumer, the less oversight there is and the greater the opportunity for something to go wrong.

Just earlier this month, multiple sunscreen companies such as Neutrogena, Sun Bum, and CVS Health, had to recall some of their products because “Valisure, a Connecticut-based online pharmacy and laboratory, found dozens of popular sunscreen products have been contaminated with benzene” (USA Today). Benzene is a toxin that, when you’re exposed to high levels over time, can cause cancer. According to an article by CNN, “no one knows for sure how the toxin ended up in sun care products. Benzene was not an ingredient in any of the sunscreens, so experts suspect contamination had to have occurred during the manufacturing process.”

Given that we’re at the height of summer, when sunscreen sales are at their peak, it’s a pretty bad time to have to issue a recall. Companies that have highly-traceable supply chains are better prepared to handle recalls, because they’re able to more easily figure out where contaminations like this occurred, and isolate which inventory was affected, without recalling more product than is necessary. Especially when poorly handled, recalls can cost your company millions, even billions of dollars depending on the scale, as well as tarnish your brand’s reputation. It’s important to understand the many facets of recall management, so that you can be better prepared in the event of one.

Counterfeit Malfunctions to Contamination

Why recalls happen and how they affect your business

In an article on recall crisis management, author Narendar Sumukadas notes how “with the supervision of government agencies, product recalls seem to have become almost weekly occurrences.” The fact that recalls are on the rise “may be attributed to the increasing complexity of the global supply chain. To cut costs and remain competitive, modern merchandise incorporates manufactured parts from around the world, sometimes at the cost of reliability.”

There are many reasons why recalls happen—from mistakes during manufacturing that lead to faulty products, to counterfeit parts making their way into the supply chain. In fact, product recalls are one reason why it’s so important for companies to double down on anti-counterfeiting measures. Ars Technica reported on chip shortages that are leading to an increase of counterfeit chips in technology-based products during the pandemic.

“Counterfeiters are well aware of the time pressure facing companies and structure their pitch to target them. [They] can compel a desperate manufacturer to cut corners and forget its normal supply chain verification process. But putting failure-prone counterfeit parts in a product only staves off the crisis. In most cases, it’s a question of whether that company loses money now due to idle lines or loses it later due to product replacements, lawsuits, and mass recalls.” Ars Technica

Knowing exactly what is going into each product, and where your sourced materials are coming from, can help identify if corners are being cut at any step of the manufacturing process. Having better supply chain visibility also gives you better insight into your own inventory, so that in times of increased demand, you can be better prepared. It also means that you’ll have better insight into tracing and tracking which products have been affected in a recall scenario. One of the reasons why recalls can be so costly is because companies often don’t have great insight into how many products were affected, so they recall too many. Having real-time tracking data for each individual product that tells the story of its entire journey through the supply chain means that you only recall the products that were affected, and nothing more.

Preparation, Not Reparation

How to have great recall management

Having a secure and traceable supply chain is something you don’t need until you really need it. And by that point it’s too late to implement the tools needed to solve your problems. Sumukadas similarly argues that “poor traceability is an expensive mistake waiting to happen”. Unfortunately, it can be difficult to get buy-in before a mistake happens.

“Many managers still see product traceability as expensive and thus difficult to justify. Unfortunately, that attitude can be counterproductive. If a product recall occurs, managers need to isolate the problem quickly to prevent a far-reaching crisis.”

The list of actions in the chart below shows just some of the many ways you can better prepare yourself for a potential recall.

How to be Prepared for a Recall:

- Introduce closed-loop manufacturing (circularity)

- Expand social responsibility targets & focus on ethical sourcing

- Improve traceability and real time inventory visibility

- Employ product identifcation

- Ensure good record keeping procedures

- Explore blockchain for traceability across supply chain Incentivize customer registration

Source: “Are you ready for your next product recall crisis? Lessons from operations and supply chain management”. Narendar Sumukadas. 2021.

Many of the actions listed here are initiatives that Vi3 has written extensively about—such as social responsibility, ethical sourcing, circularity, traceability and supply chain visibility, among others.

With Vi3’s suite of tools, you can implement hyper-unique, individualized trackers to each of your products (and each of your source materials), so you know exactly where your materials are coming from and where your products are in their life cycle. Our private blockchain ensures both security and an immutable ledger of data, which is specific to your company and you have access to, in real time. These details can make a huge difference for companies. While many large companies have the legacy, and money, to come back from a recall, “smaller ones operate without robust cash flow and brand recognition, making them more susceptible to financial losses and brand degradation” (Investopedia). Regardless of how large your company is, having systems in place to help you manage a recall when it does happen can make all the difference.

“Traceability is an important enabler of supply chain responsiveness and a best practice adopted by exemplar firms… An impressive example is presented by clothing supplier Zara, whose ability to track all materials in real time has enabled it to develop a super responsive supply chain.”

Sumukadas. 2021

Don’t wait for disaster to strike to have a plan in place. Investing in a traceable supply chain using Vi3’s tools will only help you meet your long-term goals, while providing valuable insights in the near term. Our team of expert consultants are willing to work with you to reach each of your goals, and ensure you’re prepared for the future. Reach out today.