Introduction

Why would you want to serialize all your products?

It’s easy to feel like the problems of today’s world are insurmountable. From issues that can often feel outside of our day-to-day work, like the environmental crisis, to unethical labor practices across supply chains and an over $500 billion counterfeit market, it’s fair to say that businesses have a lot to consider when making decisions. Luckily, there’s a simple investment that can help tackle a lot of these issues simultaneously—serialization.

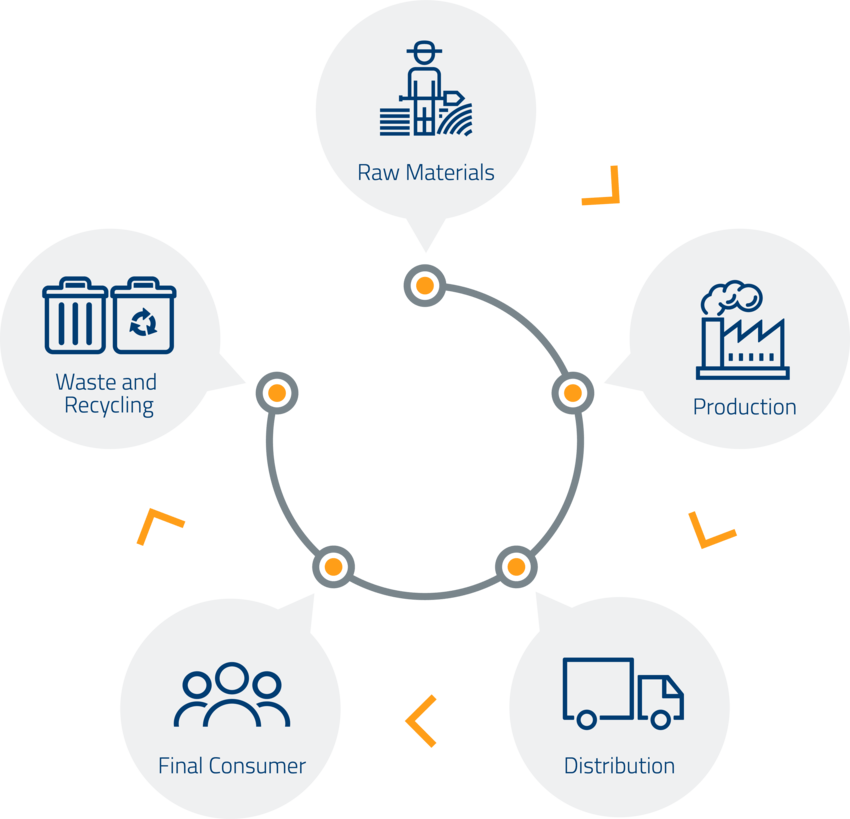

Serialization is the process of embedding unique identifiers at a unit, and even raw material level, so that everything from your materials to your final products can be traced throughout your entire supply chain. But why would anyone want to serialize each of their products? The answers lie in every level of your supply chain—from tracking raw material input and output to ensure your products are only being constructed from the sources you want (thereby reducing contamination), to streamlining your recall plans, serializing each of your products gives you an unprecedented amount of oversight, data, and control. Serialization is also a major enabler for consumer engagement, and is one of the few ways you can connect with them directly. Our clients have seen that consumers who interact with QR codes are more likely to purchase cross-promoted products.

More than anything, serializing your products is setting your infrastructure for the future. From counterfeiting to sustainability pressure—none of the issues businesses are facing now are set to decline in coming years. And with mandated recycling programs set to go in place in the EU by 2025, companies will need to be able to declare exactly what the product is made of and how old it is, before recycling them. The only way to do so accurately is through serialization. Serialization empowers you to make the most educated decisions possible now and prepare for the future, while saving you money at virtually every level.

Especially within the fashion and apparel, pharmaceutical, and food industries, waste, contamination, and counterfeits pose huge threats to consumer safety, brand reputation, and our planet. Serialization helps you track your progress, trace your products, and quantify your progress on important initiatives. In this in-depth article, we tackle the benefits of serialization through every step of your supply chain.

Early Supply Chain Benefits

Traceability, Inventory Control, Transparency

Traceability is just a fancy word for better oversight. It means being able to answer the questions, Do you know where all your products come from? Are manufactured? Which channels are they distributed in? It means being able to track the journey of a product from raw material to consumer goods, all the way into the hands of the consumer, and even after. Protecting your brand begins at the manufacturing process. Say you’ve decided to switch to a raw materials supplier who has more sustainable farming practices. This is great progress, but especially with many companies using overseas manufacturers, how can you be sure your products are only being made with this material? Incorporating unique identifiers, starting with your materials, will let you know if more end products are being produced than the material that is scanned accounts for. This is how you are able to identify contamination within the manufacturing stage of your supply chain.

Having such specific insight into your supply chain is a lot easier when you have reliable data. According to the World Economic Forum, “merging serialization – assigning unique identifiers to products ranging from consumer goods to complex medical devices – with smart manufacturing and traceability is the first step towards complete, end-to-end visibility over supply chains”. Once you have this level of visibility, you’ll be able to see when delays happen, when products are shipped and how much product you can expect in a shipment, ensure quality materials are being used, and better keep track of when you have too much inventory.

This last point is a big one. Before the pandemic, deadstock (unused) textiles cost the fashion industry around $120 billion a year—a number that’s only increased in the last year and a half (Fortune). Not only is this waste costing businesses millions of dollars a year, as we’ve reported on again and again, the fashion industry is a huge contributor to the world’s waste and pollution. Today’s consumers are demanding that brands take action. A national survey conducted by Pew Research reported that, “more than six-in-ten Americans say large businesses and corporations (69%) … are doing too little to address climate change”. A majority of those are millennials and Gen Z’ers. The choice is clear for businesses—either get a grip on your sourcing and waste problems, or lose the buy-in from this next generation of consumers.

“Sustainability issues are also creeping up more widely as investors become more aware of the problems in the industry. In their own interests, companies in this space must embrace sustainability or risk alienating customers and investors” (Fortune).

In order to mitigate the risk of being performative in your sustainability goals, you’ll need accurate data. Serialization grants you data at a granular level—allowing you to measure progress and report on that progress to consumers. The benefits are two-fold: you’re able to track tangible goals and therefore hold your company accountable to them, and your transparency around the matter will become one of your most valuable marketing tools to consumers.

Distribution and Marketplace Benefits

Anti-counterfeiting, Authentication, Returns Processing

As noted earlier, the counterfeit market is a beast. Companies spend millions of dollars each year fighting lawsuits against fakes, and employing people to physically verify the authenticity of products post-production. According to The Counterfeit Report, “Paris-based luxury goods conglomerate LVMH Moët Hennessy Louis Vuitton…employs dozens of civil and criminal enforcement lawyers across the globe and spends a reported $17 million annually on anti-counterfeiting legal action in connection with its stable of brands, including Louis Vuitton, Dior, Celine, Givenchy, and Loewe.”

Companies are also using new artificial intelligence technology to authenticate products in stores. Wall Street Journal reported how Entrupy sells a camera with AI technology that super-magnifies the fabric of material goods so that retailers can check things like the color, stitching, and patterns of a product. The technology becomes better at recognizing fakes over time, as it gathers more data. However this is all done post-manufacturing, when the counterfeit product has already made it to distributors. Once a fake is in distribution, it becomes a lot more difficult to control.

Instead of taking a reactive approach, serializing your products with unique, scannable identifiers will aggregate scans into a database, so that you can see any illegitimate or duplicate scans from counterfeit products. Doing so will help you pinpoint where the counterfeit activity is stemming from, and where it’s being distributed to. Further combining serialization with blockchain technology ensures that your data is stored securely and cannot be tampered with.

Today, enterprise blockchain technology…is creating a cost-efficient foundation for supply chain transparency. Rather than being an aspirational vision, a shared, near-real-time record of truth can now be recorded and accessed by members of an ecosystem…This technological breakthrough has now made it possible to quickly verify the authenticity of products such as premium olive oil or fair trade coffee, as well as the origin and processing of “conflict-free” minerals.”

IBM

The rise of serialization and blockchain has created the perfect solution for anti-counterfeiting measures and point-of-sale authentication. With a simple scan you can verify where the product has come from, what its contents are, and if it can be traced back to the original brand. This point of sale authentication system also comes in handy with returns processing. According to the National Retail Federation, 5.9% of returns in 2020 were fraudulent, “equating to $25.3 billion” in losses. Return fraud has further increased throughout the pandemic, where fraudsters are taking advantage of more lenient online returns policies. With serialized products, each transaction can be traced, so that customer returns can be more easily verified.

End of Product Life Benefits

Consumer Marketing, Recall Management, Recycling & Circularity

The data companies get from serializing their products doesn’t only help companies make smarter decisions for the future, it also helps them better manage the inventory they have now. By incorporating serialization into your supply chain at a unit level, “marketing teams will be better equipped with timely information regarding sales of their products, allowing them to adjust marketing tactics as needed. If supply of a specific product is high and sales are low, the company can run a special to promote the product” (Supply Chain Brain). These targeted marketing decisions will help limit product waste, sell remaining supply, and reach a different segment of the population—the price-sensitive customer.

Then there’s the issue of quality control. Unfortunately, quality issues typically mean one of two things—returns or recalls. But with serialization, “if a quality escape should occur, the returned product can be scanned, queried, and analyzed, allowing larger issues to be addressed and mitigated proactively” (Forbes). Most returns don’t make it back into circulation and get resold and, according to Forbes “$1 million in returns can potentially erode $500,000 in profits, prompting many major retailers to simply allow shoppers to keep merchandise rather than process a costly return.” But recalls are even more costly. The average cost of a food recall is $10 million, and that’s because of a lack of traceability. Without serialization, companies are left to err on the side of caution or risk further harming consumers and damaging their brand, thereby recalling mass amounts of product that may or may not be affected by the issue. “The big advantage of traceability is that if there is an error and a complaint comes from that, we can determine precisely which products, lot, or batch is affected. Thus we can limit impact” (Johann Weber, CEO of Zollner Electronics, via Forbes).

“Imagine the benefits this would have provided during the romaine lettuce recalls that surfaced last year. Consumers could have determined whether the item was at risk simply by entering a serial number into a website. Stores could have understood which products were safe to keep on shelves, and which needed to be pulled. Manufacturers would have better understood where the contaminated products were shipped, and communicated directly with those specific locations.”

Supply Chain Brain

Being able to accurately determine where manufacturing errors happen allows you to cut the price of a recall by determining which products were affected, as well as help mitigate those issues in the future.

Another topic we run into at this stage of the manufacturing cycle is recycling and circularity programs. If you’re considering utilizing old products for new usage to help eliminate waste in your supply chain, serialization will help you track what percentage of old products are being returned for recycled purposes. Similarly to how serialization helps you determine when sustainable sources are being used for raw materials, these end-of-life uses for used goods can be tracked to help determine circularity and sustainability goals, and report on your progress.

All in all, there’s a lot that happens to products after they’re sold, and in many ways, these continue to impact the business. Serialization makes reverse logistics, recalls, and recycling run that much more smoothly.

The Vi3 Edge

How our suite of tools helps you tackle serialization from end to end and back again

At Vi3, we know a thing or two about serialization and the importance of secure, reliable, and accurate data. We combine hyper-unique serialization codes with our carbon-neutral blockchain technology to ensure your materials and products are tagged, traced, and reported on in one accessible platform. The importance of secure, reliable data in today’s world where data breaches and counterfeiting is commonplace, cannot be overstressed.

“Disruptive technologies, such as…blockchain and collaborative platforms, can take traceability systems to another level” (World Economic Forum). Major companies are investing in this technology now, because they know its impact is going to be a key differentiator when it comes to customer retention and satisfaction. In fact, “Zara’s parent company Inditex has invested $2.7 billion in the technological integration of its stores, tagging every article of clothing with a radio frequency identification (RFID) chip to have mass data of their clothes to streamline demand and supply” (Fortune). But RFID technology is flawed when it comes to recycling. The RFID tag itself must be removed and deconstructed for proper recycling, and they pose a major recycling issue. With our suite of tools, you can rest easy knowing you’re not further contributing to this issue, while getting your traceability needs met.

Having good data informs better decision making and allows you to run towards your goals at a much more rapid pace. Good data also enables you to increase transparency with your consumers, building brand trust, loyalty, and empowering your customer to make smarter decisions with you.

Interested in how we can work together to serialize your supply chain? Our trusted advisors are always here to talk.